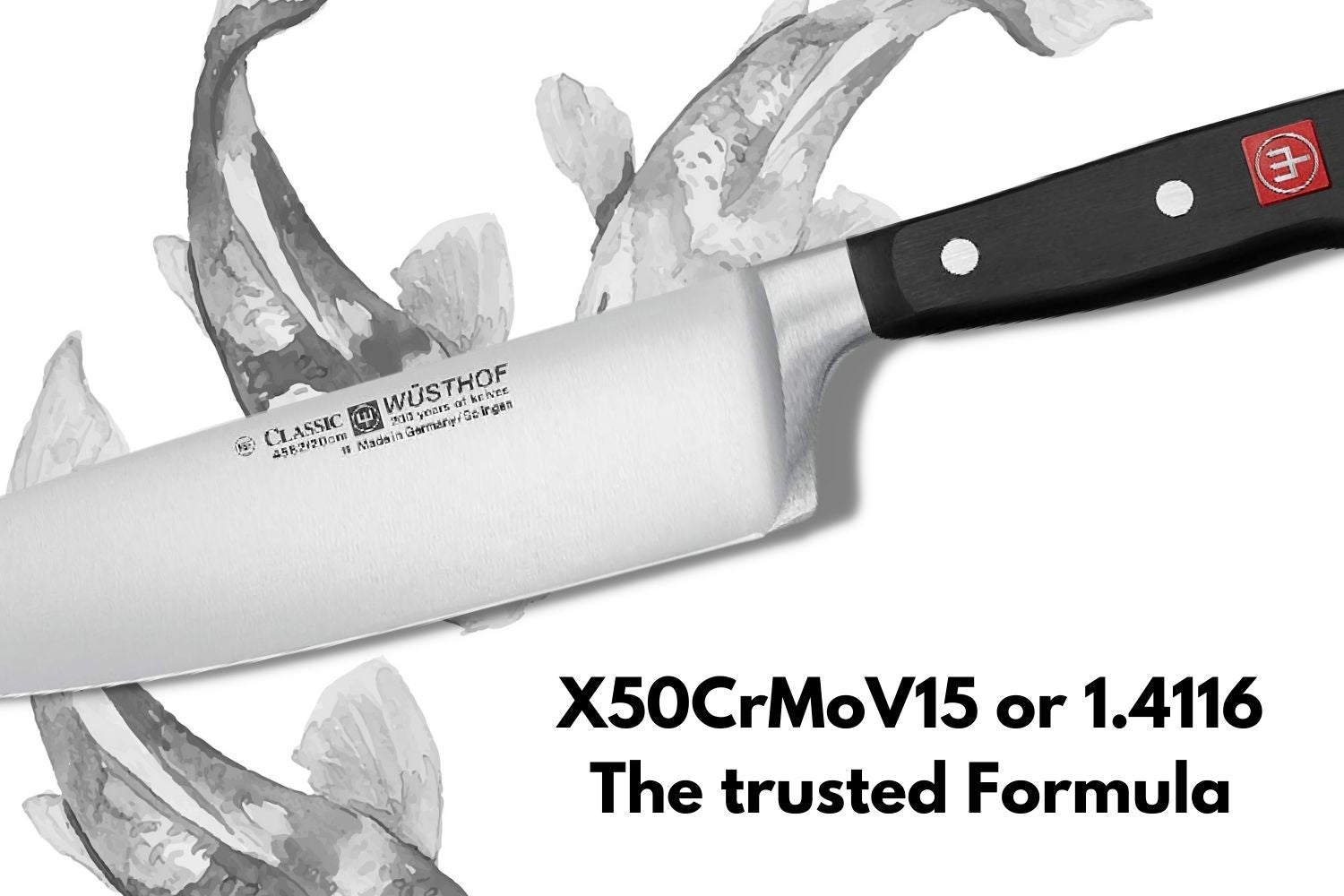

The stainless steel X50CRMOV15 is renowned for its excellent mechanical qualities, strong corrosion resilience, and toughness. The 1.4116 steel is commonly used in cutlery, culinary knives, and other fine cutting tools like scalpels. It is well known for producing Swiss Army Knives.

While you're here, check out our range of Koi Knives

The German steel, also known as 1.4116, is not your ordinary steel alloy. Due to its different chemical make-up, which endows it with various extraordinary features, this steel has become a well-liked option over time.

The characteristics, make-up, and applications of 1.4116 steel are covered in more detail as you continue reading. We'll also go through how to maintain and sharpen this steel.

What Exactly Is 1.4116 Steel?

1.4116 steel has a martensitic microstructure and is stainless steel. The 1.4116 steel, also known as X50CrMoV steel, is a steel type produced by German manufacturer ThyssenKrupp. While 1.4116 steel is mostly recognised for its ability to withstand corrosion and wear, it is also notable for being simple to sharpen and moderate edge retention.

The 1.4116 steel material is designated as X50CrMoV15 by the DIN standards and naming system. The 'X' represents the stainless steel alloy, '50' refers to the 0.5% Carbon, the 'CrMoV' stands for chromium, molybdenum, and vanadium chemical formula, and finally the '15' is the percentage of Chromium. Its performance is comparable to AUS-8 steel but with somewhat superior corrosion resistance.

Composition of 1.4116 Steel

- 0.55 % Carbon C: Enhances hardness, structural rigidity, and edge retention. Furthermore, it increases the steel's rust, corrosion, and wear resistance.

- 15.00% Chromium Cr: Chromium carbide increases the blade's tensile strength, hardness, and corrosion resistance.

- 0.20% Vanadium V: prevents grain formation during elevated temperature processing and heat treatment, increasing steel strength and toughness. It also creates carbides, which improve wear resistance.

- 0.80% Molybdenum Mo: boosts hot hardness and toughness. Additionally, it enhances hardenability and produces carbides that are resistant to wear.

- 0.04% Phosphorous P: Despite being viewed as an impurity, it may increase steel's strength and process-ability.

- 1.00% Manganese Mn: enhances the steel's tensile strength and hardness. Increased manganese during the heat-treatment of the steel enhances its capacity to harden.

- 1.00% Silicon Si: improves toughness and heat resistance.

- 0.02% Sulfur S: enhances machinability, but excessive amounts are considered impurities.

Iron (Fe), carbon, and other micro-elements, including chromium, vanadium, molybdenum, phosphorus, manganese, and silicon, are the major constituents of 1.4116 steel. The 0.55 percent carbon component boosts the material's tensile strength and abrasion resistance.

Although they are recognised contaminants, phosphorus and sulphur are added in modest amounts to improve formability. The steel's capacity to be hardened is enhanced by adding manganese during heat treatment.

How Do the Qualities of 1.4116 Steel Fare as a Material for Kitchen Knives?

The ideal kitchen knife material should have a balance of the desired qualities. High corrosion resistance, ease of sharpening, and hardness make the 1.4116 steel a choice.

The effects of 1.4116 steel in each of these parameters are shown below:

Hardness

The 1.4116 steel has a Rockwell hardness of 54-57 HRC, classifying it as low hardness steel. The fundamental cause for its hardness is the low carbon content.

German kitchen knives are relatively soft, with hardness levels ranging from 54 HRC for bigger blades such as cleavers to 56 HRC for smaller knives such as chef knives. Because smaller knives require higher edge holding, tougher 1.4116 steels are employed.

Corrosion Resistance

The 1.4116 steel has a chromium content of 15%, making it corrosion resistant. Because of its great corrosion resistance, the steel is food safe and may be used in professional settings.

German kitchen knives are built to last and must endure dampness, acids, and other harsh substances. Because of its resistance to corrosion and stains, 1.4116 steel is very simple to maintain.

Edge Sharpness

Because of the low carbon content, the 1.4116 steel is not as hard as high carbon steel and does not keep an edge as well as other steel varieties. While it will not dull quickly, you must sharpen the knife more frequently.

Toughness

Although it's not the strongest steel on the market, 1.4116 steel is strong enough for most culinary duties. The steel is suitable for everyday kitchen knives since it is resistant to breakage and chipping. It produces a kitchen knife that is essentially perfect in terms of hardness and toughness.

Toughness is even further enhanced by the intermediate carbide contents present in 1.4116. The carbides aren't in large measure to make the steel fragile, and they aren't too little to considerably boost hardness either (HRC).

Durability

Knives must be wear-resistant since a broken edge might cause chipping. Molybdenum is a component in 1.4116 steel that improves wear resistance.

Although it doesn't rust as quickly as other steel, it is crucial to keep the knife polished and avoid using it extensively without cleaning thoroughly. Small rust formations can appear on the steel cladding if kept wet or stored incorrectly. Abrasive diamond compounds can quickly remove these rust deposits if needed.

Also, always use a ceramic honing rod to maintain the edge's sharpness without wearing down the steel.

1.4116 Steel Compared to Other Steels

Let's Contrast1.4116 steel to different steels:

1.4116 Compared to D2 Steel

Carbon makes up 1.40 to 1.60 percent of D2 steel, which has greater wear resistance due to its high hardness qualities due to its high carbon content. Additionally, it guarantees that the steel keeps its edge longer than 1.4116 steel.

D2 lacks enough chromium to qualify as stainless steel. As a result, it lacks the anti-corrosion qualities of 1.4116 steel. It is mostly employed in industrial uses like cutting tools and punches but is costlier than 1.4116 steel.

1.4116 Steel Compared to 440C Stainless Steel

Stainless steel with a 17–18% chromium concentration is known as 440C steel. Compared to the 0.55 percent carbon content of 1.4116 steel, it has a greater carbon content of 1.1 percent. This carbon increases its hardness and wear resistance while improving its edge retention qualities.

While both types of steel are very simple to sharpen, 440C steel is costlier than 1.4116 steel.

1.4116 Steel Compared to 7Cr17mov Steel

Chinese stainless steel 7Cr17MoV has a carbon content of 0.7% and a chromium content of 17%-18%. It has great corrosion resistance due to the high chromium concentration and hardness qualities due to the carbon presence.

Due to its higher toughness and superior edge retention over 1.4116 steel, 7Cr17MoV is common steel used to make combat knives.

1.4116 Steel Knife Sharpening Tips

1.4116 is mild steel that is simple to sharpen. To avoid harming the blade, utilise the proper sharpening equipment and methods.

To sharpen your 1.4116 steel knife, check if the sharpening stone is clean and debris-free. Begin with a coarse grit stone and work up to a finer grit.

If you have trouble sharpening a knife made of 1.4116 steel, you can have it professionally honed. Most knife repair businesses will perform a good job returning the edge to its previous strength for a modest fee.

FAQs About 1.4116 Steel

Is 1.4116 Steel Suitable for Knife Making?

Knifemakers use the 1.4116 steel because of its outstanding corrosion and wear resistance. A great example is the Wüsthof knife brand, established in Solingen, Germany, more than 200 years ago and has earned a reputation for form, function, and unwavering quality.

What Are the Disadvantages of 1.4116 Steel?

1.4116 has moderate edge retention and must be sharpened frequently to keep its edge. Furthermore, because it is not as sturdy as certain other knife steels, it may not be suitable for heavy-duty tasks.

Conclusion

X50CrMoV15, sometimes referred to as 1.4116 steel, is martensitic stainless steel. Due to its exceptional wear and corrosion resistance characteristics, it is used to produce knives and other cutting instruments. Besides kitchen knives and other precision cutting tools like medical scalpels, the steel is attributed to Swiss Army Knives.